Home > News > Industry News > Details

The sustainable development of paper packaging testing instruments is inseparable from the development of related standards. According to the statistics in the catalog of the national paper industry standardization system, there are about 360 types of paper products, and there are more than 160 related test methods and standards. Among them, physical There are 85 standards for mechanical performance test methods. In addition, there are more than 50 standard items related to the raw materials, semi-finished products and finished products of carton products.

In order to meet the urgent needs of papermaking and carton product quality testing, and to implement relevant test methods and standards, paper packaging testing instruments currently require more than 70 varieties and specifications on the market. The responsibility of the paper packaging testing instrument industry is the development and production of special instruments and various special instruments. The basic situation of various paper packaging testing instruments at present is as follows:

1.Paper and paperboard basic properties testing equipment

This includes measuring instruments for quantitative, thickness, tightness, moisture, absorbency and other properties, and is the most commonly used basic instrument. This type of instrument includes: digital quantitative tester, manual thickness meter, electric thickness meter, high-precision thickness tightness meter, manual corrugated cardboard thickness meter, electric corrugated cardboard thickness meter, digital display corrugated cardboard thickness meter, variable pressure thickness meter There are more than a dozen varieties of general moisture analyzers, rapid moisture analyzers, simple absorption analyzers, flip-type absorption analyzers, absorption height analyzers, etc. These varieties can basically meet actual needs.

2. Paper and cardboard strength performance testing instrument

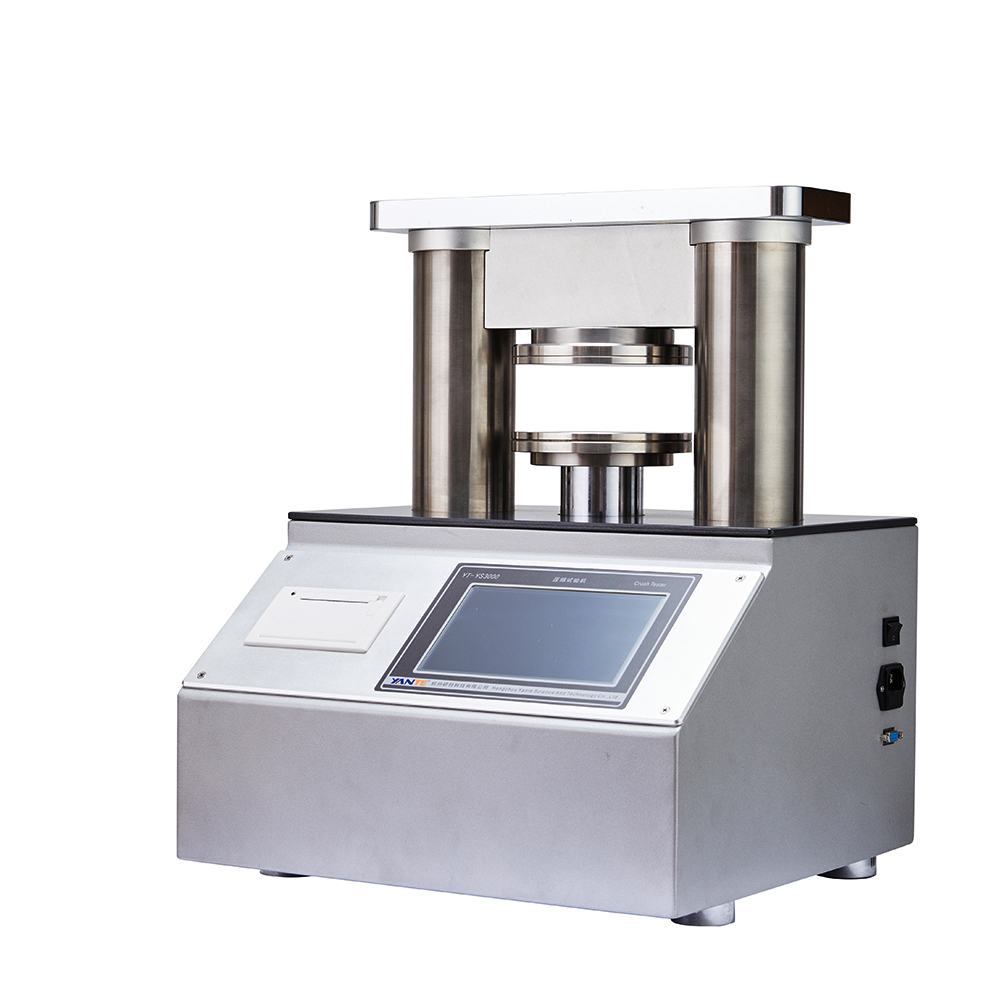

Strength performance refers to physical properties, which include tensile strength, compressive strength, burst strength, puncture strength, tear strength, bending strength, folding fatigue strength, short sapn compressive strength and internal bonding strength, etc. Performance testing equipment, these physical testing is the leading instrument for testing the strength performance of paper and paperboard. Such instruments include: constant speed loading method pendulum tensile testing machine (there are four types of specifications), constant speed tensile method electronic tensile testing machine (there are more than ten types of specifications), cardboard compression tester ( There are multiple structures), carton compression tester (three specifications, multiple structures), paper burst tester, cardboard burst tester, Puncture Resistance Tester, Taber stiffness tester, digital Taber stiffness tester.There are more than 30 varieties of tester, MIT folding tester, Schuber-type folding tester, multi-pendulum tear tester, digital tear tear tester, short span compression tester, etc. This is a paper packaging inspection instrument The leading product is also the foundation.

3.Paper and cardboard printing suitability testing instrument

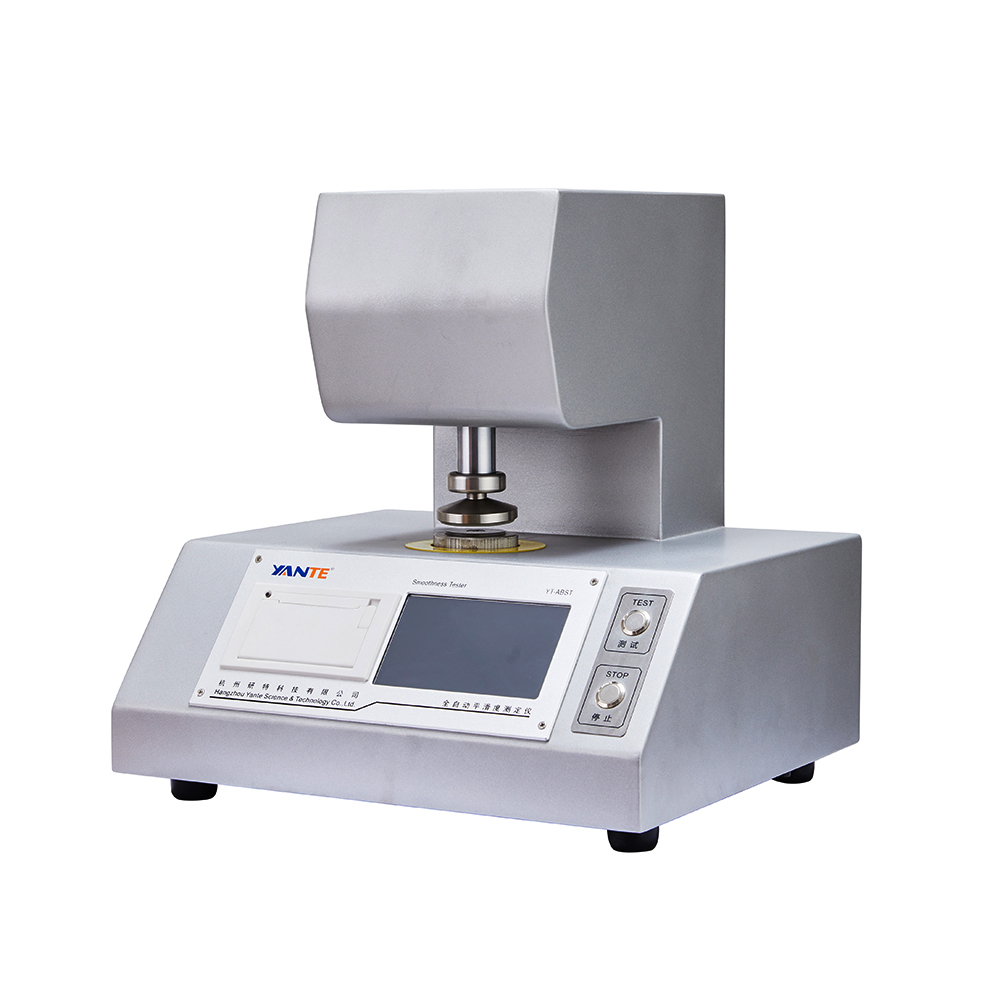

Testing instruments such as the smoothness, roughness, and surface strength of the printed surface are important instruments with higher technical requirements and greater manufacturing difficulties in performance testing instruments. Such instruments include: Bekk smoothness tester, Bentesen roughness tester, printing surface roughness tester (PPS), pendulum IGT tester (commonly known as napping tester), electric IGT tester (also known as multifunctional printing adaptor) Sex tester) and so on. This type of instrument is widely used in the 38 product standards of printing paper and cardboard in my country, but at present, only Bekk smoothness meters and pendulum-type IGT meters can be produced in China, PPS instruments (roughness testers) ,many high-end printing papers have long been used. and electric IGT instruments can only rely on imports. This is a problem that the paper packaging testing instrument industry should work harder to solve in the future, and it is also the bottleneck of the current domestic market.

4. Some special properties testing instruments for paper and cardboard

In this category, there are specific testing instruments for air permeability, abrasion resistance, brightness, gloss, chroma and other properties. These special properties are very important for some high-grade paper and high-grade cardboard. Such instruments such as Schopper air permeability meter, Gurley air permeability meter, abrasion resistance tester, whiteness meter, gloss meter, etc., among which whiteness meter, gloss meter and Schober air permeability meter have been It has been in production for many years, but several other instruments have not yet been developed and produced, and basically rely on imports.

5.Paper and cardboard performance testing auxiliary instruments, appliances and various punching sample cutters

This is an indispensable and important auxiliary equipment to ensure the quality of the paper and paperboard performance testing process. Such equipment such as: Concora Medium Fluter, slurry spin dryer, standard cutter, adjustable distance cutter, quantitative test sampler(GSM sample cutter), corrugated board edge crush , flat crush, adhesive strength sampler, paper With more than ten varieties of special punches for cardboard tensile, ring crush, stiffness, tear test, and various special support appliances. At present, these auxiliary devices have been developed and produced in China, which can greatly meet the needs of customers.

6.Paper pulping slurry testing instruments

Such instruments should be strictly classified as small laboratory equipment. At present, only the Schuber-type tapping meter (beating degree meter), the Canadian freeness meter, the Dutch type 23 liter small beating machine, and simple sheet formers can be produced in China. A small number of varieties, but some very needed varieties can not be produced, such as cutting index meter, concentration meter, slurry disc mill, etc., so this type of equipment is also a weak link in the domestic testing instrument industry.

Hangzhou Yante Science And Technology Co.,Ltd.. is a high-tech enterprise in Hangzhou, mainly engaged in the research and development, production, sales and service of various intelligent testing instruments and automatic control equipment in the packaging, paper, printing, textile, cigarette, electromechanical, chemical and other industries. The company has 15 computer software copyright patents, 4 invention patents and utility model patents. It has a CMC measuring instrument manufacturing license and operates in accordance with the ISO9001 international quality management system. It is a new domestic professional testing instrument supplier with a strong sense of pioneering and innovation.

We are dedicated to independent innovation in the field of testing instruments and meters. We develop and produce special testing instruments with advanced technology, high quality and low price. The main products are whiteness meter, colorimeter, compression testing machine, horizontal (vertical) paper Computer tensile tester, smoothness tester and box compression tester are used in papermaking, packaging, chemical, printing and other industries.

"Professional, thick, honest, continuous innovation" YANTE company constantly pursue, and strive to innovate the business philosophy, to provide customers who need testing instrument with professional industry solutions and high quality services, determined to become the leader of paper and packaging testing instrument industry.

33011002013339号

33011002013339号